Maximizing Efficiency with Direct Thermal Label Printers

In today's fast-paced business environment, efficiency is key. One area where companies can significantly enhance their operational performance is through label printing. Among the various options available, direct thermal label printers stand out as a superior choice for businesses that demand high-quality, reliable, and cost-effective printing solutions. This article delves deep into the world of direct thermal label printers, exploring their benefits, applications, and why they are indispensable for modern businesses.

Understanding Direct Thermal Label Printers

A direct thermal label printer is a device that uses heat to generate images on specially coated thermal paper. Unlike thermal transfer printers, which use a ribbon to transfer ink, direct thermal printers create images by applying heat directly to the paper. This results in a crisp, clear print that is ideal for various applications such as shipping labels, barcodes, and product labels.

The Technology Behind Direct Thermal Printing

The technology of direct thermal printing involves two key components: the thermal print head and the thermal paper. When the printer’s heating elements are activated, they heat specific spots on the thermal paper, causing a chemical reaction that produces a visible image. Direct thermal label printers are renowned for their simplicity—there are no ribbons or inks to replace, thereby minimizing maintenance and operational costs.

Advantages of Using Direct Thermal Label Printers

Choosing a direct thermal label printer for your business operations offers numerous advantages:

- Cost-Effective Printing: Because they do not require ink or toner, direct thermal printers entail lower printing costs. The only recurring expense is the thermal paper itself, making them a budget-friendly option for businesses.

- Ease of Use: Direct thermal print systems are user-friendly. With minimal setup and no need for complex configurations, even novices can quickly learn to operate these devices.

- High-Speed Printing: These printers can produce labels rapidly, which is particularly beneficial in high-volume environments such as warehouses, shipping departments, and retail stores.

- Compact and Portable: Many models are designed to be compact, allowing businesses to save valuable workspace and providing the option to move the printer wherever necessary.

- No Ink Smudging: Since direct thermal printing does not use ink, the risk of smudging or running is eliminated, ensuring that labels remain clear and readable.

- Environmentally Friendly: With fewer consumables required, direct thermal printing can be considered a more environmentally conscious choice for businesses.

Applications of Direct Thermal Label Printers

The versatility of direct thermal label printers makes them suitable for a myriad of applications across various business sectors. Here are some common uses:

- Shipping and Logistics: Direct thermal label printers produce high-quality shipping labels, facilitating efficient package tracking and delivery.

- Retail: Retailers use direct thermal printing to create price tags, product labels, and barcode labels, enhancing the shopping experience and inventory management.

- Healthcare: Hospitals and clinics utilize these printers for patient wristbands and medication labels, ensuring safety and accuracy in patient care.

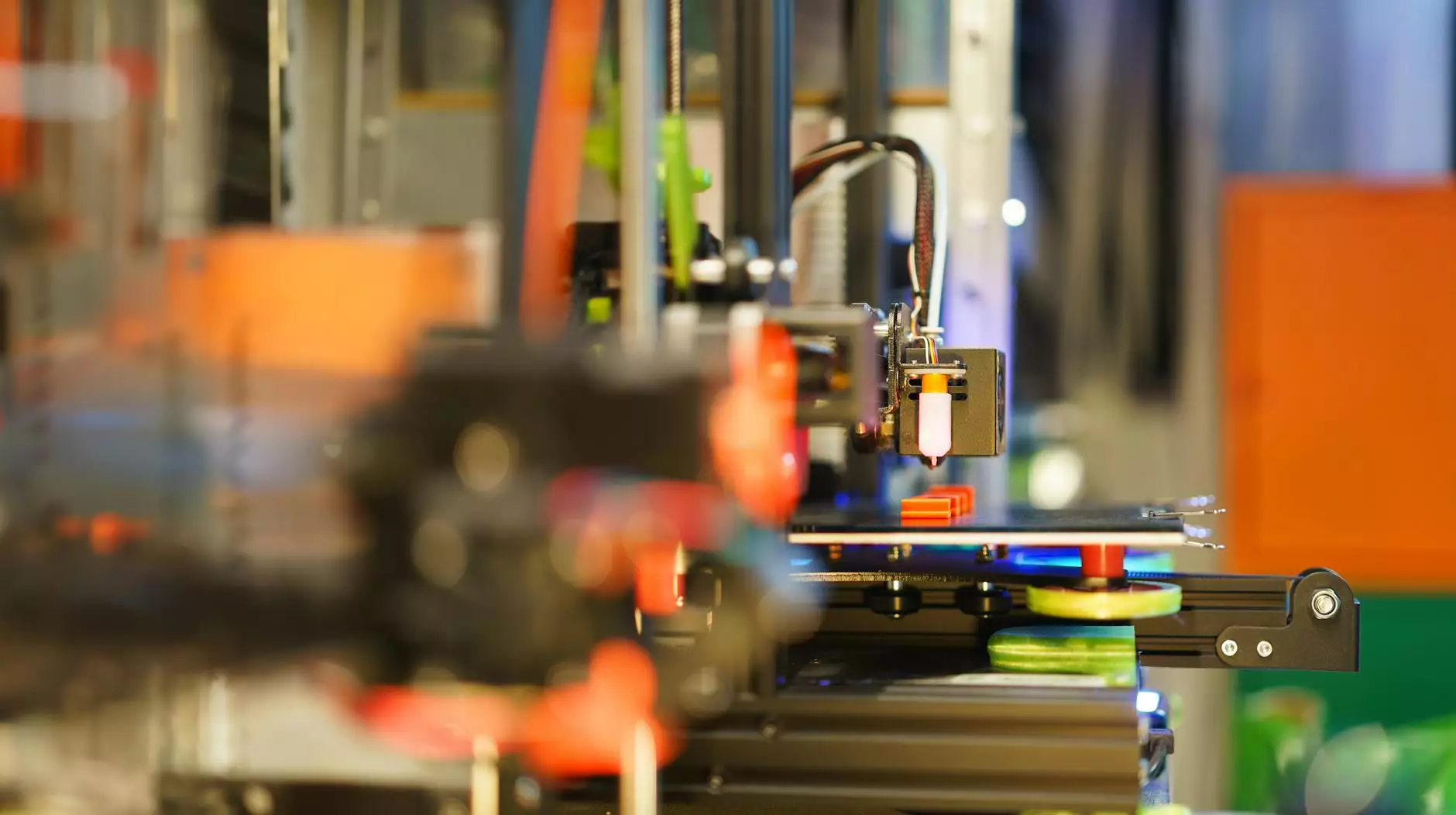

- Manufacturing: In manufacturing settings, direct thermal printers are used for labeling products, enabling organizations to maintain efficient production workflows.

- Food Services: Restaurants and catering services employ direct thermal printing to label ingredients, ensuring compliance with health regulations.

Choosing the Right Direct Thermal Label Printer

When selecting a direct thermal label printer, there are several factors to consider to ensure you choose a model that fits your business needs:

1. Print Speed and Resolution

Assess the required print speed and resolution for your operations. Faster models are better suited for high-volume printing environments, while higher resolution is critical for barcode scanning and detailed labels.

2. Connectivity Options

Consider the printer's connectivity options. Many modern printers offer USB, Ethernet, and wireless connectivity, allowing you to integrate them seamlessly into your existing systems.

3. Label Compatibility

Make sure that the printer is compatible with your preferred label sizes and types. Direct thermal printers can handle various label shapes and materials, but verifying compatibility ensures smooth operations.

4. Durability and Design

Invest in a durable printer designed for the demands of your environment. Models designed for industrial use are built to withstand harsher conditions, while more compact models are suited for office or retail settings.

Integration with Business Operations

Efficient direct thermal label printers significantly enhance business operations by integrating smoothly with inventory management systems, POS systems, and shipping software. Features like barcode generation and automatic label sizing streamline workflows, reduce errors, and save time.

By eliminating manual label creation tasks, businesses can focus more on strategic initiatives rather than routine processes. Moreover, the speed and accuracy of direct thermal label printers contribute to improved customer satisfaction through timely and error-free deliveries.

Best Practices for Maintaining Direct Thermal Label Printers

- Regular Cleaning: Clean the print head and other components regularly to prevent dust buildup and ensure high-quality prints.

- Use Compatible Thermal Paper: Always use the recommended thermal paper for your specific printer model to avoid printing issues.

- Monitor Print Quality: Periodically inspect print quality and conduct maintenance checks to catch any potential issues early.

- Update Firmware: Keep your printer's firmware updated for optimal performance and access to the latest features.

Conclusion: Transforming Your Business with Direct Thermal Label Printers

In summary, the advantages of implementing a direct thermal label printer in your business operations are overwhelmingly positive. From increased efficiency and reduced costs to improved print quality and versatility, these printers serve as a valuable asset for companies across various industries. Investing in a direct thermal label printer not only enhances logistics and operational capabilities but also positions your business for success in an increasingly competitive market.

As you consider upgrading your printing solutions, remember to evaluate the specific needs of your business and choose a direct thermal label printer that aligns with your goals. Whether you’re a small retailer or a large distribution center, harnessing the power of direct thermal printing can lead to significant improvements in productivity and customer satisfaction.